- Electronic Universal Testing Machine

-

Tensile Testing Machine

- Hydraulic universal testing machine

- Dynamic Fatigue Testing System

-

Robot Automated Testing Systems

- Impact Testing Machine Series

- Compression Testing machine

- Torsion Testing Machine

- Bending Testing Machine

- Creep and Rupture Testing Machine

-

Elastomeric Bearing Testing Machine

-

Cupping Testing Machine

- Spring Testing Machine

-

Other testing machine

- Paper and Package Test Equipment Series

- Textile Test Equipment Series

- Optical Test Equipment Series

- Spectrometer

- Testing equipment for masks and protection cover

- Plastic Pipes and Rubber Test Machine

- Other testing machine

- Video Measuring Machine

- Optical Profile Projector

- Coordinate Measuring Machine

- Force Gauge

- Mechanical Machine

- Hardness Tester

-

NDT Series

-

Microscope

- Metallographic

- Testing machine accessories

- High And Low Temperature Chamber

-

Insulator Testing Machine

-

Friction and Wear Testing Machine

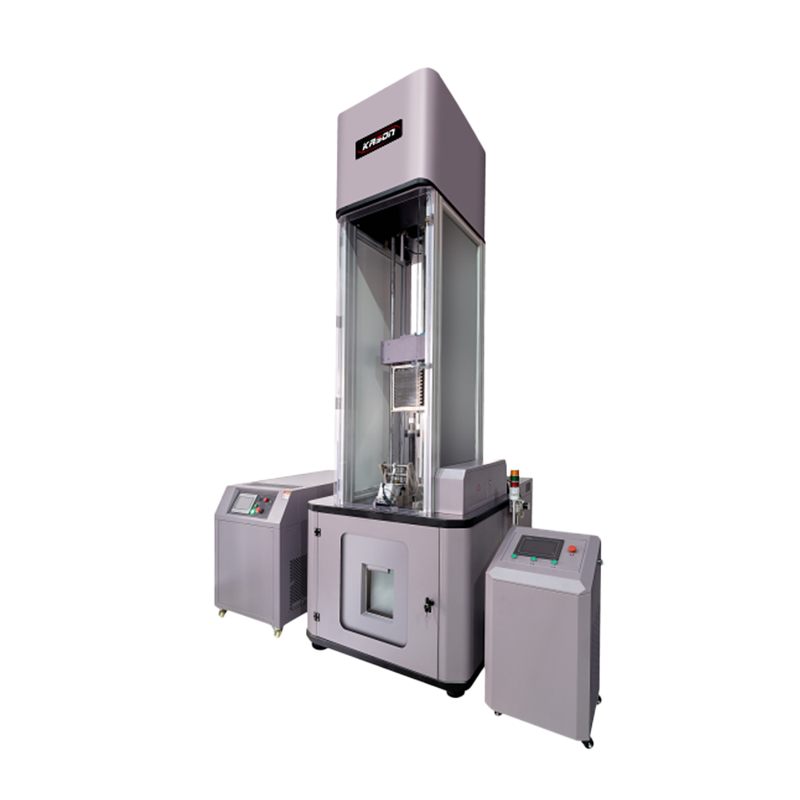

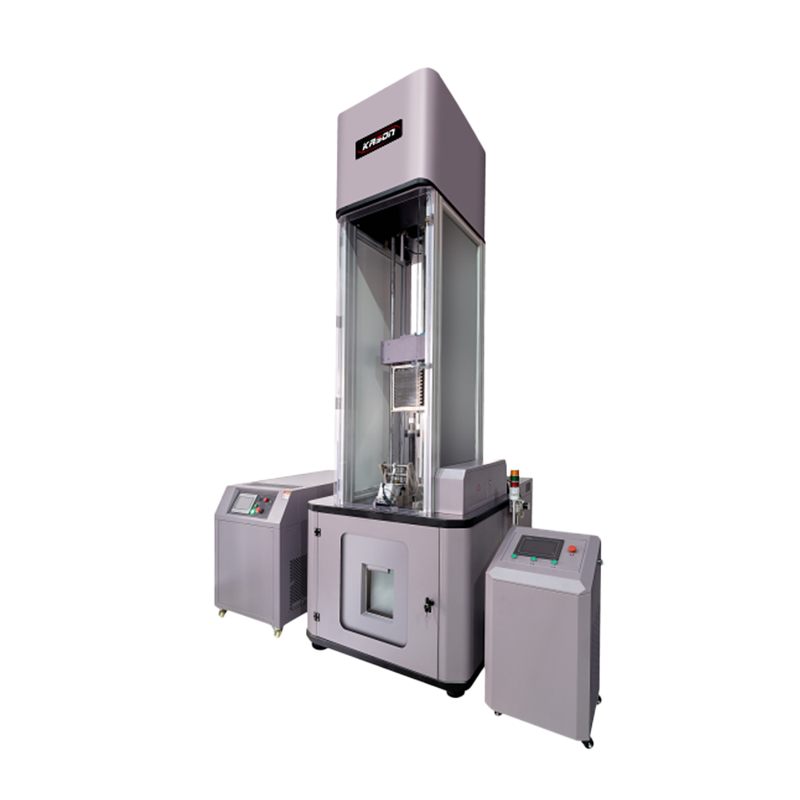

KASON-DIT1800E Ejection Impact Testing Machine

Application

The ejection Drop Weight Impact Testing machine is mainly a Testing equipment for Testing the impact resistance of various metal and non-metal pipes and plates (including various non-metal materials such as plastics, ceramics, nylon, building materials, etc.). The impact force value sensor and test system are used, and the high-speed data acquisition card uses the oscilloscope impact sensor to measure the load and deformation transient values during the fracture process of the impacted sample, that is, the impact absorbed energy, the force-displacement-energy curve and the curve during the impact process.

Standards

ASTM D 7136/D 7136M-05,ASTM D 3763-02,ASTM E 23-07a

Specifications

|

Model |

KASON- DIT1800E |

|

Impact energy |

6~1800J |

|

Impact speed |

1.6~20m/s |

|

impact height |

0.1~1.2m(Simulation up to 20m) |

|

maximum impact speed |

7m/s~20m/s(70kg~3kg) |

|

Hammer lifting speed |

1m/min~3m/min Continuous adjustable |

|

Hammer head positioning accuracy |

1mm |

|

Maximum load of impact force sensor |

100kN |

|

Impact force value sensor static linear error |

Full range ±1%(10%~50%FS) Point by point ±2%(50%~100%FS) |

|

A/D sampling resolution |

16bits |

|

Maximum sampling frequency |

2MHz |

|

Frequency response |

500kHz |

|

Channel storage capacity |

60000 |

|

Experimental dynamic error |

<2% |

|

Test area space |

720mm×660mm×580mm |

|

Testing Machine dimensions |

920×860mm×3300mm |

|

Testing machine net weight |

1200kg |

|

power supply |

220V±10%,50Hz±10%,3kw |