- Electronic Universal Testing Machine

-

Tensile Testing Machine

- Hydraulic universal testing machine

- Dynamic Fatigue Testing System

-

Robot Automated Testing Systems

- Impact Testing Machine Series

- Compression Testing machine

- Torsion Testing Machine

- Bending Testing Machine

- Creep and Rupture Testing Machine

-

Elastomeric Bearing Testing Machine

-

Cupping Testing Machine

- Spring Testing Machine

-

Other testing machine

- Paper and Package Test Equipment Series

- Textile Test Equipment Series

- Optical Test Equipment Series

- Spectrometer

- Testing equipment for masks and protection cover

- Plastic Pipes and Rubber Test Machine

- Other testing machine

- Video Measuring Machine

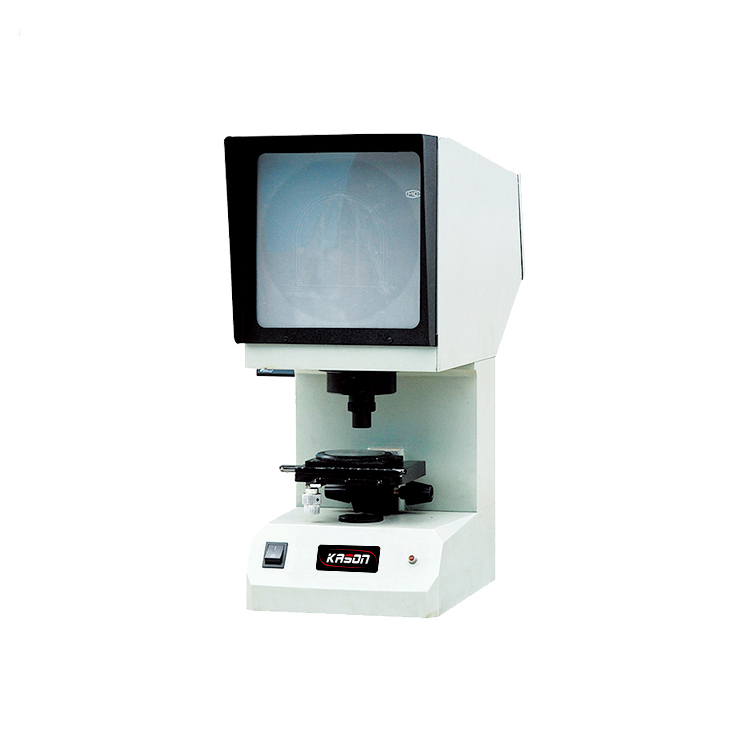

- Optical Profile Projector

- Coordinate Measuring Machine

- Force Gauge

- Mechanical Machine

- Hardness Tester

-

NDT Series

-

Microscope

- Metallographic

- Testing machine accessories

- High And Low Temperature Chamber

-

Insulator Testing Machine

-

Friction and Wear Testing Machine

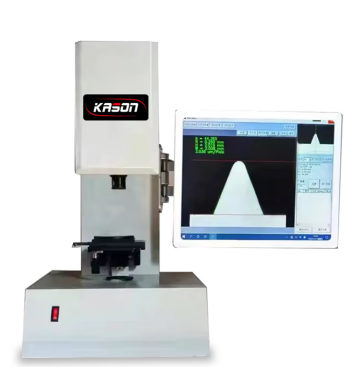

KASON IMG-15 Impact specimen notch imaging instrument

Application

IMG-15 impact specimen notch imaging instrument is a special optical instrument designed and developed by us according to the actual needs of domestic users and the requirements of impact specimen notch in GB/ T229-2020 "Metal Charpy Notch Impact Test Method", which is dedicated to checking the quality of Charpy V and U impact specimen notch processing. By using optical imaging method, the impact sample V or U-shaped notch profile is amplified and transformed to the computer display screen, and the impact sample V and U-shaped notch standard sample are programmed to determine whether the notch processing of the tested impact sample is qualified. Its advantages are simple operation, intuitive inspection and comparison, and high efficiency.

Feature

This imager is a new measurement technology. The product contour is reduced tens of times through the telecenter lens and then transferred to the five million pixel high-resolution CCD camera for digital processing. Then the background mapping and measurement software with powerful computing power can quickly capture the product contour according to pre-programmed instructions. Finally, the product size is calculated by comparing with the scale formed by the small pixel points of the high pixel camera, and the dimensional tolerance is evaluated.

Specifications

|

MODEL |

KASON IMG-15 |

|

Display size |

15 inches |

|

Working table square shape |

110x125mm;Round table Φ90 mm; Workbench glass diameter: Φ70 mm |

|

Stroke of working table |

Longitude: ±10mm,Latitude: ±10mm,Rise and fall: ±12mm |

|

Scope of revolving of the worktable |

0 ° -360 ° |

|

Camera acquisition pixels |

5 million |

|

Objective lens magnification |

2.5X |

|

Projection lens magnification |

20x |

|

Light source (LED) |

12V 100W |

|

Power supply |

220V,50HZ |

|

Dimension |

450×350×650mm |

|

Weight |

about 26kg |