- Electronic Universal Testing Machine

-

Tensile Testing Machine

- Hydraulic universal testing machine

- Dynamic Fatigue Testing System

-

Robot Automated Testing Systems

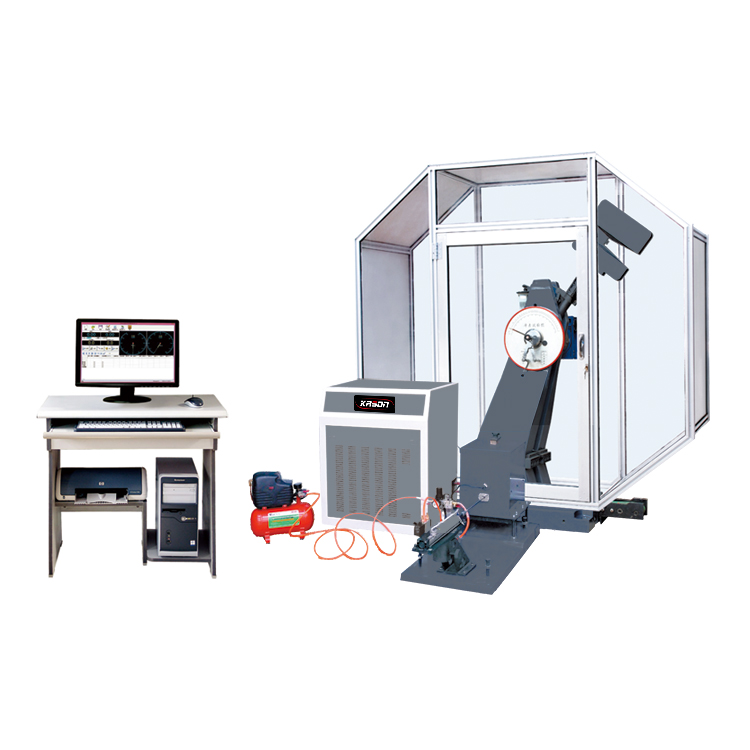

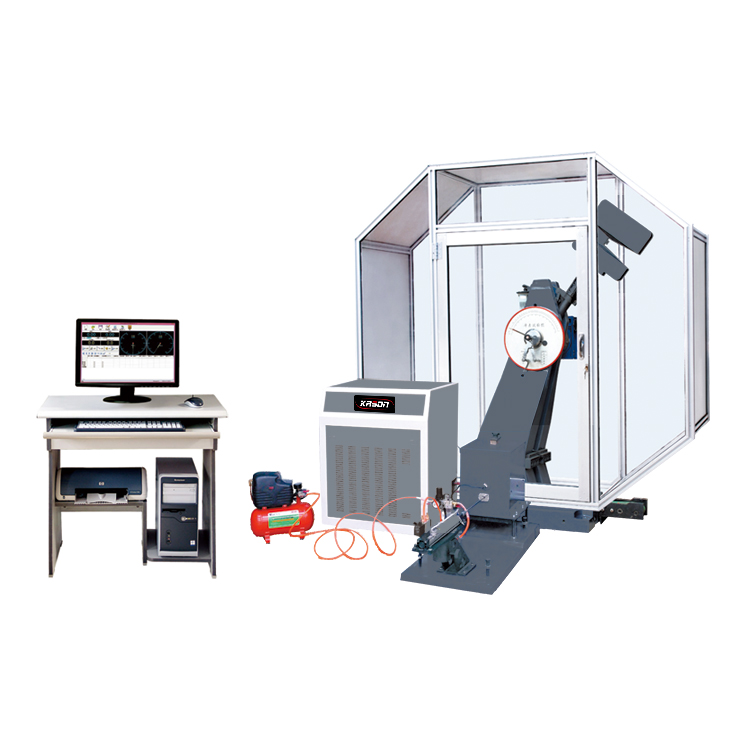

- Impact Testing Machine Series

- Compression Testing machine

- Torsion Testing Machine

- Bending Testing Machine

- Creep and Rupture Testing Machine

-

Elastomeric Bearing Testing Machine

-

Cupping Testing Machine

- Spring Testing Machine

-

Other testing machine

- Paper and Package Test Equipment Series

- Textile Test Equipment Series

- Optical Test Equipment Series

- Spectrometer

- Testing equipment for masks and protection cover

- Plastic Pipes and Rubber Test Machine

- Other testing machine

- Video Measuring Machine

- Optical Profile Projector

- Coordinate Measuring Machine

- Force Gauge

- Mechanical Machine

- Hardness Tester

-

NDT Series

-

Microscope

- Metallographic

- Testing machine accessories

- High And Low Temperature Chamber

-

Insulator Testing Machine

-

Friction and Wear Testing Machine

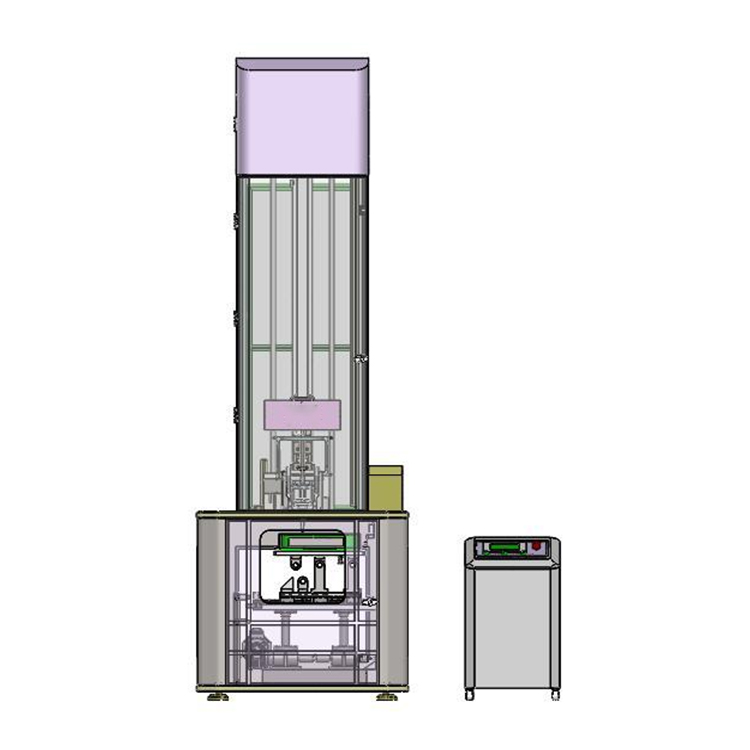

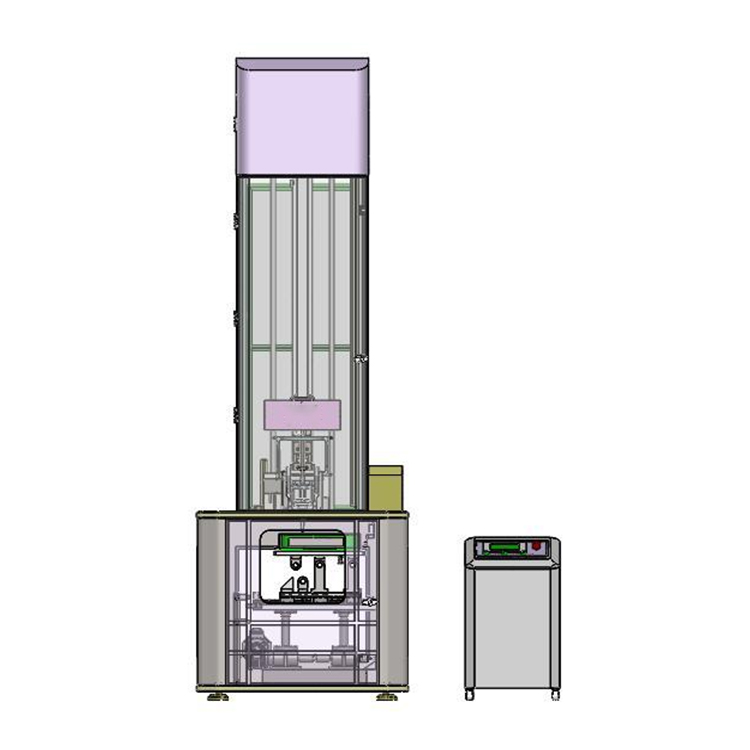

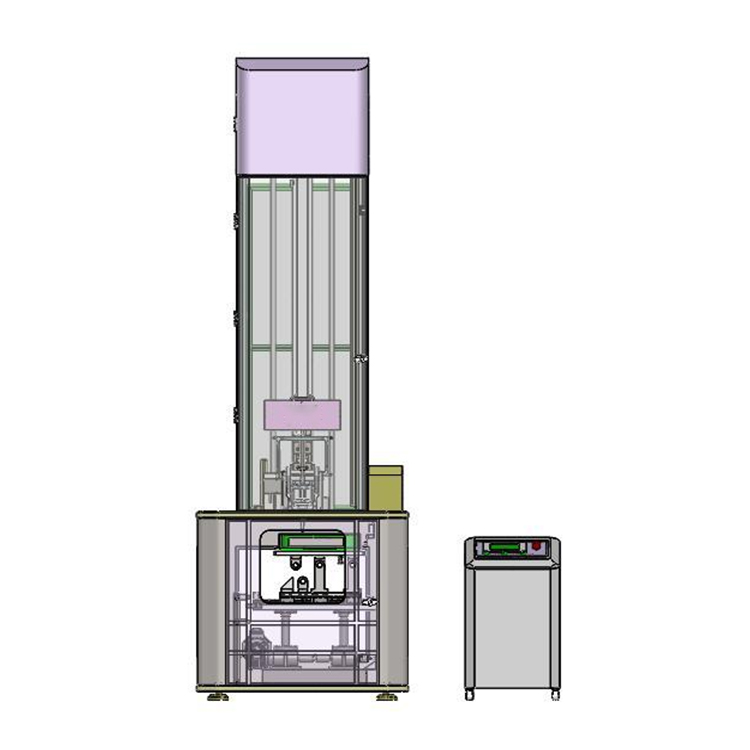

KASON-DWT-300IG Anti-stab Clothing Drop Weight Impact Testing Machine

Application:

KASON-DWT-300IG instrumented drop hammer impact Tester is mainly used to Test the puncture performance of anti-stab clothing. It uses impact force sensor, test system, and high-speed data acquisition card to measure the load and deformation transient value of the impacted sample fracture process through oscilloscope impact sensor, that is, impact absorption work, force-displacement-energy curve of the impact process and characteristic points on the curve: maximum force Fm, total impact energy Wt and corresponding displacement and other parameters.

Performance parameters:

|

Maximum impact energy |

300J |

|

Impact speed |

1.98~5.42m/s |

|

Impact height |

0.2~1.5m |

|

Range of hammer mass |

10kg |

|

Mass error of hammer and weight |

±1% |

|

Range of hammer |

1~3m/min(Continuously adjustable) |

|

Positioning accuracy of hammer head |

1mm |

|

Maximum load of impact force sensor |

20kN |

|

A/D sampling resolution |

16bits |

|

Maximum sampling frequency |

2MHz |

|

Frequency response |

500kHz |

|

Dynamic error of experiment |

<2% |

|

Dimensions of Testing Machine |

1120mm*900mm*3600mm |

|

Net weight of Testing machine |

Approx.1500kg |

|

Power supply |

Mainframe:AC 220V±10%,50Hz,2kW High and low temperature box:AC 380V±10%,50Hz,6.5kW |