- Electronic Universal Testing Machine

-

Tensile Testing Machine

- Hydraulic universal testing machine

- Dynamic Fatigue Testing System

-

Robot Automated Testing Systems

- Impact Testing Machine Series

- Compression Testing machine

- Torsion Testing Machine

- Bending Testing Machine

- Creep and Rupture Testing Machine

-

Elastomeric Bearing Testing Machine

-

Cupping Testing Machine

- Spring Testing Machine

-

Other testing machine

- Paper and Package Test Equipment Series

- Textile Test Equipment Series

- Optical Test Equipment Series

- Spectrometer

- Testing equipment for masks and protection cover

- Plastic Pipes and Rubber Test Machine

- Other testing machine

- Video Measuring Machine

- Optical Profile Projector

- Coordinate Measuring Machine

- Force Gauge

- Mechanical Machine

- Hardness Tester

-

NDT Series

-

Microscope

- Metallographic

- Testing machine accessories

- High And Low Temperature Chamber

-

Insulator Testing Machine

-

Friction and Wear Testing Machine

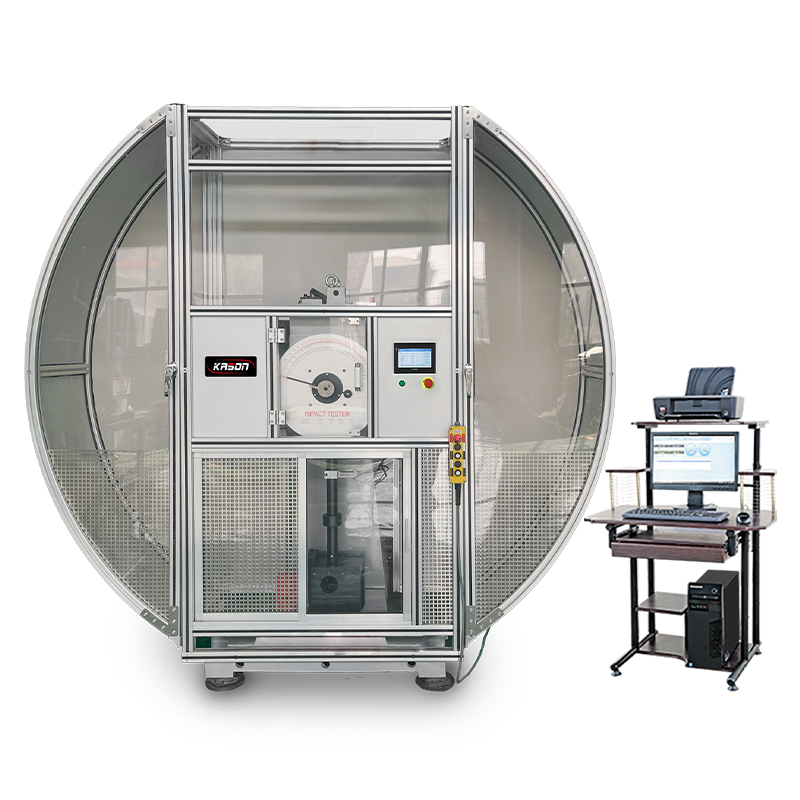

KASON PIT-CH Touch Screen variable-angle Pendulum Impact Testing Machine

1. Introduction

KASON PIT-CH Pendulum Impact Testing Machine meet the growing demand for accurate and repeatable impact testing of metallic materials in accordance with ASTM and ISO specifications. They are EN 10045-2 ‘CHARPY impact test on metallic materials’ – Method for the verification of impact testing machines and ASTM E 23, ‘Standard test methods for notched bar impact testing of metallic materials’. As a general guideline, in North America, most users prefer verifications to the ASTM E 23 method while Europe generally require EN 10045-2 verifications.

JBS-CH double columns metal pendulum impact testing machine is an improved model of the C-type old metal pendulum. It retains the advantages of the JBS-CH-type testing machine such as stability, and eliminates the disadvantage of the clutch being easy to wear when the C-type pendulum makes a large-energy impact. It improves the service life of the equipment when the large-energy impact occurs, and at the same time increases the impact function at any angle.

2. Standards:

ISO 148-1 -《Metallic materials — Charpy pendulum impact test 》

JIS Z 2242 -Method for CHARPY pendulum impact test of metallic materials.

EN 10045-1 -Metallic materials-CHARPY impact test.

ASTM E23 (CHARPY) -Standard test method for notched bar impact testing of metallic materials.

GOST 9454-78 -Impact bending test method at low, room and high temperatures.

|

Model |

KASON PIT-452CH |

KASON PIT-752CH |

|

|

Display model |

with analogue dial gauge, touch screen display, can optional Software and RS232 cable connect computer |

||

|

Max. impact energy |

J |

450 |

750 |

|

Analog display |

|

Included |

|

|

Optional pendulum |

J |

150,300,450 |

150,300,450,600,750 |

|

Pendulum moment 150J |

Nm |

80.3848 |

|

|

Pendulum moment 300J |

150.7695 |

||

|

Pendulum moment 450J |

241.1543 |

||

|

Pendulum moment 600J |

321.5390 |

||

|

Pendulum moment 750J |

401.9238 |

||

|

Angle resolution |

° |

0.025 |

|

|

Striking angle |

° |

30-150 adjustable |

|

|

Distance from support axis to percussion center |

mm |

750 |

|

|

Striking velocity |

m/s |

5.24 |

|

|

Support span |

mm |

40 |

|

|

Radius of support curvature |

mm |

1~1.5 |

|

|

Angle of support taper |

° |

11±1 |

|

|

Striking edge radius |

mm |

2 (R2) or 8 (R8) |

|

|

Striking thickness |

mm |

16 |

|

|

Striking tip angle |

mm |

30 |

|

|

Specimen dimensions |

mm |

55x10x10 |

|

|

mm |

55x10x7.5 |

||

|

mm |

55x10x5 |

||

|

Motor power |

kW |

1 |

|

|

Power supply |

V-Hz-ph |

400-50/60-3

|

|

|

Dimensions |

mm |

2200x800x2150 |

|

|

Weight |

kg |

800 |

|