- Electronic Universal Testing Machine

-

Tensile Testing Machine

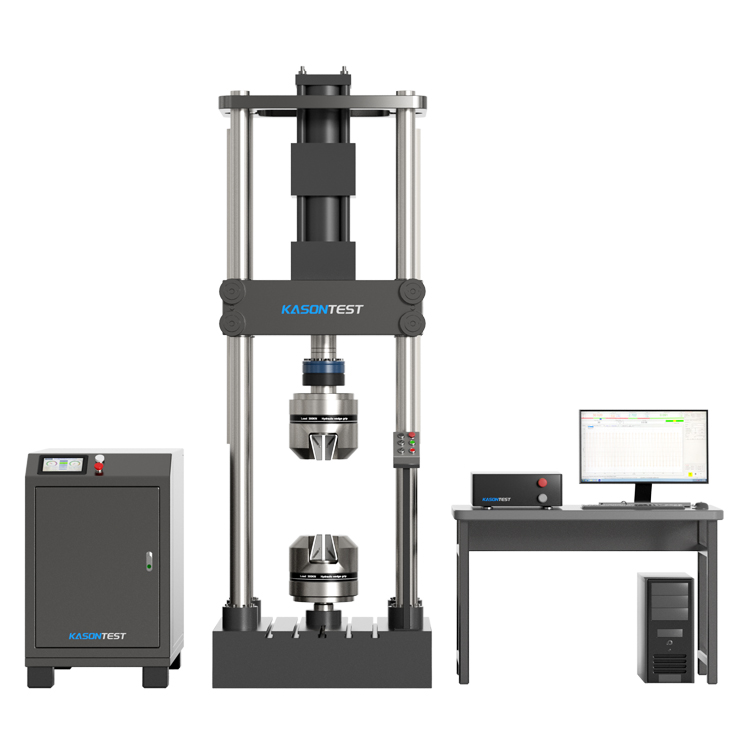

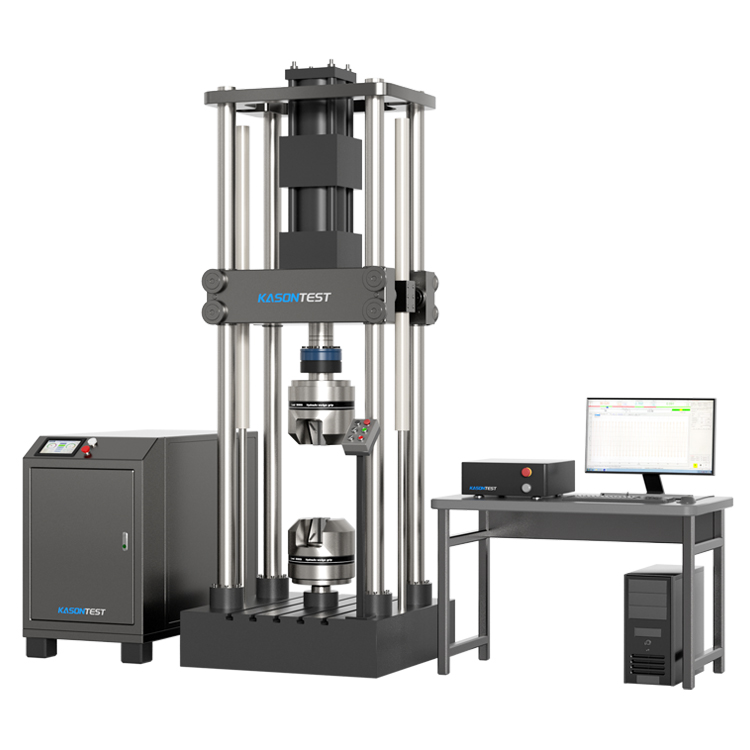

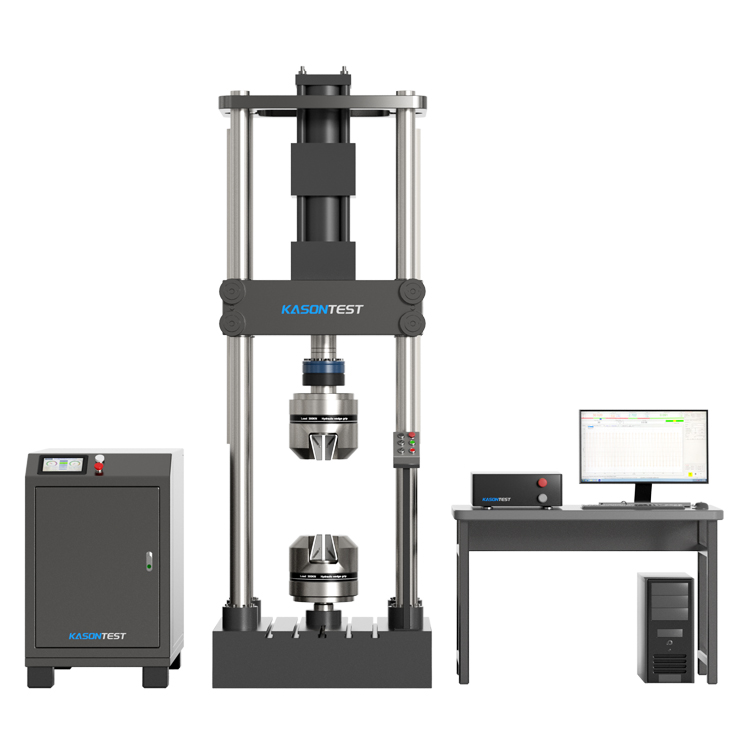

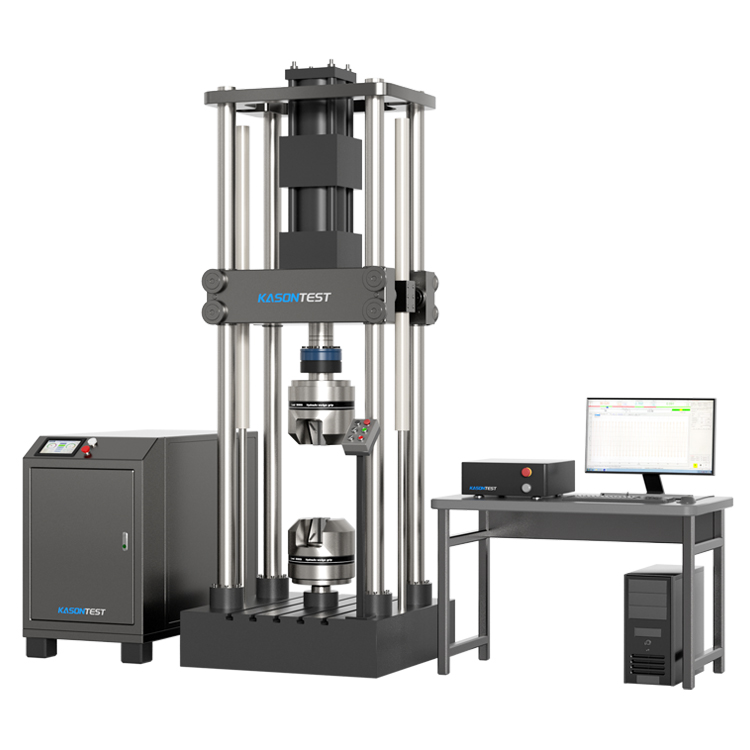

- Hydraulic universal testing machine

- Dynamic Fatigue Testing System

-

Robot Automated Testing Systems

- Impact Testing Machine Series

- Compression Testing machine

- Torsion Testing Machine

- Bending Testing Machine

- Creep and Rupture Testing Machine

-

Elastomeric Bearing Testing Machine

-

Cupping Testing Machine

- Spring Testing Machine

-

Other testing machine

- Paper and Package Test Equipment Series

- Textile Test Equipment Series

- Optical Test Equipment Series

- Spectrometer

- Testing equipment for masks and protection cover

- Plastic Pipes and Rubber Test Machine

- Other testing machine

- Video Measuring Machine

- Optical Profile Projector

- Coordinate Measuring Machine

- Force Gauge

- Mechanical Machine

- Hardness Tester

-

NDT Series

-

Microscope

- Metallographic

- Testing machine accessories

- High And Low Temperature Chamber

-

Insulator Testing Machine

-

Friction and Wear Testing Machine

500 kn dynamic fatigue testing machine High-frequency dynamic and static fatigue testing machine

1. Application

This series computer Control Electro-hydraulic Servo Fatigue Testing Machine is mainly used to detect a variety of metals, non-metallic materials and small movable member, the static mechanical properties test. It can do tensile, compression, bending, low cycle and high cycle fatigue, crack growth, fracture mechanics test under sine, triangle, square wave, trapezoidal wave, random wave, combination waveform.

This Test machine is flexible, moving beam down, locking the sample holder by button operations, the use of advanced hydraulic servo drive technology loaded, high precision and high resolution dynamic load sensor magnetostrictive displacement sensor specimens force values and displacement.

Fully digital measurement and control system implementation force, displacement, deformation closed loop control, Software powerful data processing capabilities, test conditions and test results are automatically saved, displayed and printed. Fully integrated into the computer-controlled test procedure, the test machine is a research institutes, metallurgy building, defense industry, universities, machinery manufacturing, transportation and other industries ideal cost-effective test systems.

2. Standards

GB / T2611-2007 《Tester General technical requirements》

GB / T16826-2008 《Hydraulic servo universal testing machine》

GB 3075 《Axial fatigue testing metal》

JB / T9379-2002 《Tension and compression fatigue test machine technical conditions》

GB / T228-2010 《Metallic materials at room temperature tensile test method 》

HB5287 Axial Loading Fatigue Test Method for Metal Materials

EN10002 Tensile Test of Metallic Materials

JJG 556-2011 Axial Force Fatigue Testing Machine

HG/T 2067-1991 Technical specifications for rubber fatigue testing machine

ASTM E399-09 Metallic materials Kic standard test for linear elastic plane strain fracture toughness

ASTM E1820 2001 test standard for measuring fracture toughness

3. Specifications

|

Model |

KASON HDT505A |

|

Force capacity |

500kN |

|

Load range |

2%-100%FS |

|

Testing machine accuracy |

Static indication accuracy: ±0.5% Dynamic loading accuracy: ±1% |

|

Actuator dynamic stroke |

|

|

Displacement measuring range |

0~150mm(±75mm) |

|

Displacement measurement resolution |

0.001mm |

|

Deformation indication relative error |

±0.5% |

|

Force coaxiality |

≤5% |

|

Frequency Range |

0.01-20HZ (50Hz optional) |

|

Effective distance between columns |

762×310mm |

|

Maximum test space |

1200mm (exclude hydraulic clamps) |

|

Main test waveforms |

Sine wave, square wave, triangle wave, ramp wave, random waveform and external input waveform; can realize multiple sine wave forms with different frequency or amplitude combinations; random wave forms with user-defined parameters; user-imported custom wave forms |

|

Test control method |

Load, displacement, deformation control method |

|

Servo pump station specifications |

Flow 100L/min, 21Mpa |

|

Power supply |

AC 380V± 10%, 50Hz |