- Electronic Universal Testing Machine

-

Tensile Testing Machine

- Hydraulic universal testing machine

- Dynamic Fatigue Testing System

-

Robot Automated Testing Systems

- Impact Testing Machine Series

- Compression Testing machine

- Torsion Testing Machine

- Bending Testing Machine

- Creep and Rupture Testing Machine

-

Elastomeric Bearing Testing Machine

-

Cupping Testing Machine

- Spring Testing Machine

-

Other testing machine

- Paper and Package Test Equipment Series

- Textile Test Equipment Series

- Optical Test Equipment Series

- Spectrometer

- Testing equipment for masks and protection cover

- Plastic Pipes and Rubber Test Machine

- Other testing machine

- Video Measuring Machine

- Optical Profile Projector

- Coordinate Measuring Machine

- Force Gauge

- Mechanical Machine

- Hardness Tester

-

NDT Series

-

Microscope

- Metallographic

- Testing machine accessories

- High And Low Temperature Chamber

-

Insulator Testing Machine

-

Friction and Wear Testing Machine

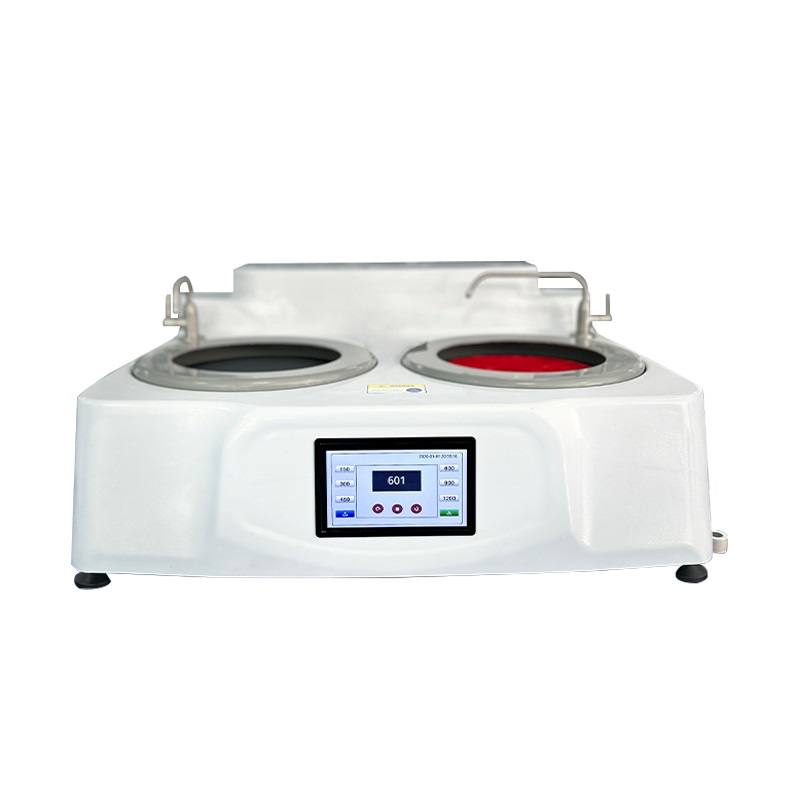

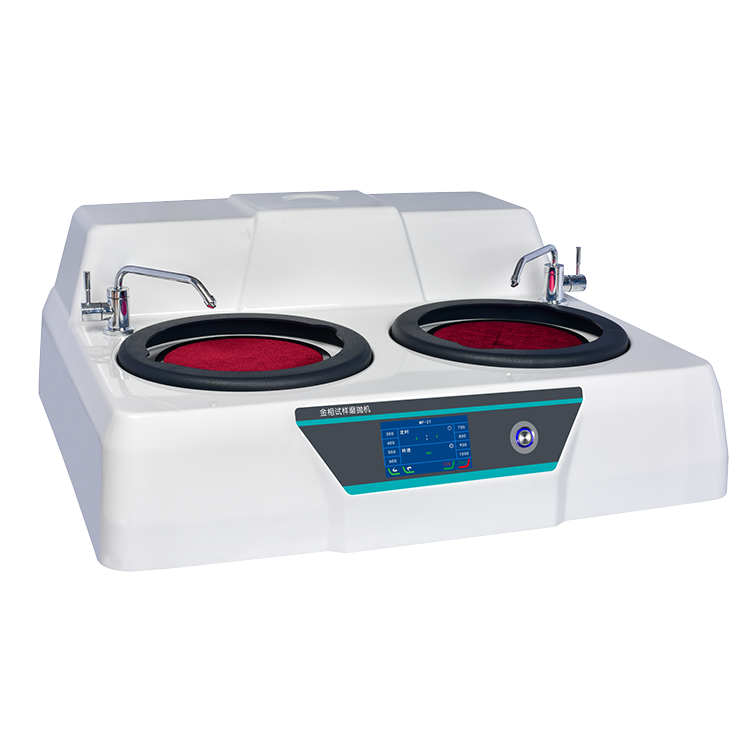

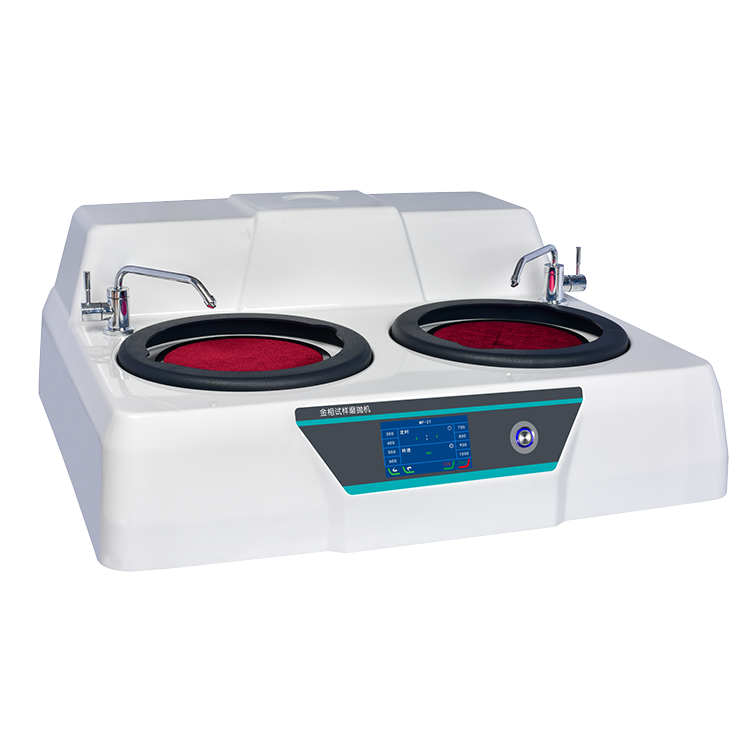

KS-MP2T Metallographic grinding polishing machine

1、Introduction:

In the process of metallographic specimen preparation, grinding and polishing of the specimen are essential procedures. After grinding and polishing, the specimen can obtain a mirror-like surface. The MP-2T metallographic specimen grinding and polishing machine adopts a high-end touch screen, which can make the speed of the grinding and polishing disc infinitely adjustable between 50-1000r/min. By replacing the metallographic sandpaper and polishing fabric, the grinding and polishing process of the specimen can be completed, showing a wider range of applicability. The shell adopts overall blister, with a novel appearance, and has the characteristics of stable rotation, low noise, convenient operation, high work efficiency, etc. It also has a built-in cooling device, which can cool the specimen during grinding and polishing to prevent the metallographic structure from being damaged due to overheating of the specimen. It is suitable for metallographic laboratories in factories, colleges and universities, and scientific research institutions. It is an excellent equipment for grinding and polishing metallographic specimens.

2、Technical parameters:

|

Grinding disc diameter |

Standard φ203mm (other specifications can be customized) |

|

Grinding disc speed |

50-1000r/min (stepless speed regulation) |

|

Grinding disc speed |

Eight-speed fixed speed |

|

Grinding disc rotation direction |

Forward and reverse |

|

Power supply |

Voltage: 220V Frequency: 50HZ |

|

Motor |

0.55KW |

|

Dimensions |

730×765×320mm |

|

Weight |

42Kg |