A shipment of advanced Charpy & Izod integrated impact Testing Machines, developed by a prominent Chinese precision equipment manufacturer, is scheduled to depart for France this month. Comprising 150 units tailored to European industry standards, this delivery responds to the escalating demand for versatile material impact resistance Testing solutions in France’s manufacturing, construction, and research sectors, marking a key milestone in Sino-French technical equipment cooperation.

The integrated Testing machines distinguish themselves with groundbreaking dual-functionality and superior performance. Unlike traditional single-mode devices, they seamlessly combine Charpy and Izod testing capabilities, eliminating the need for cumbersome equipment replacement and significantly improving testing efficiency by up to 40%. Equipped with a high-sensitivity force sensor and digital signal processing system, the machines achieve a test accuracy of ±0.3% within a force range of 1J to 500J, ensuring reliable data for evaluating the toughness and impact resistance of materials such as steel, plastic, rubber, and composite materials.

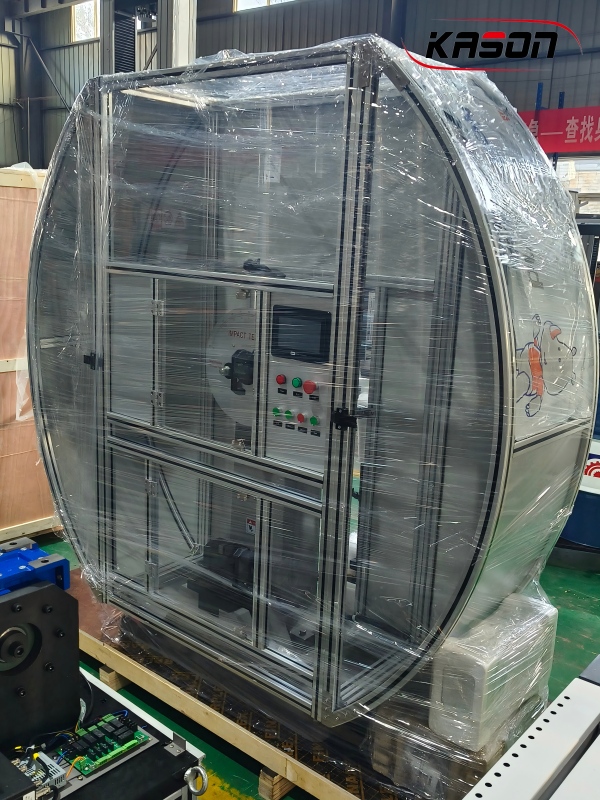

Structural innovation is another core advantage of the equipment. The rigid frame, forged from high-quality carbon steel, minimizes deformation during high-impact tests, while the ergonomic design features an adjustable test bench and quick-change fixtures, allowing operators to switch between Charpy (notched and unnotched) and Izod test modes in less than two minutes. The integrated machine also incorporates an intelligent control system with a multilingual touchscreen interface, supporting automatic test parameter setting, real-time data visualization, and compliance with international standards including ISO 179, ASTM D256, and EN 10045.

Safety and sustainability are prioritized in the machine’s design. It is equipped with a full-enclosed safety guard, anti-rebound mechanism, and emergency stop system to prevent operator injury during high-energy impact tests. Additionally, the adoption of an energy-efficient motor and low-power consumption components reduces the machine’s carbon footprint by 20% compared to conventional models, aligning with France’s green manufacturing initiatives. The low-vibration operation (≤0.5g) and noise level (≤55dB) also make it suitable for laboratory and production line environments alike.

French partners, including leading automotive component manufacturers and material research laboratories, have praised the equipment’s versatility and precision. “This integrated solution addresses our need for efficient, accurate impact testing across multiple materials, helping us accelerate product development and quality control processes,” commented a technical director from a French automotive supplier. “The compliance with European standards and user-friendly design make it a valuable addition to our testing facilities.”

The export of these Charpy & Izod integrated testing machines underscores China’s growing strength in high-precision testing equipment manufacturing and reinforces technological exchange between the two countries. The manufacturer emphasized its commitment to continuous R&D, stating that it will further optimize product performance based on European market feedback and expand its global footprint, delivering innovative testing solutions to support industries worldwide.

Sales02@jnkason.com

Whatsapp: +86 17860598665