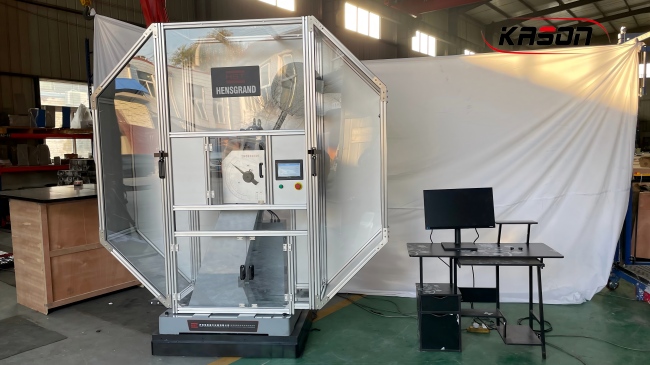

A state-of-the-art impact Testing Machine, independently developed by a leading Chinese precision equipment manufacturer, is in the final phase of assembly and debugging and will be shipped to Turkey by the end of this month. This shipment signifies a new milestone in the export of China’s high-end material Testing equipment to the Middle East and European markets, demonstrating the manufacturer’s rising influence in the global Testing equipment industry.

Custom-built for a prominent Turkish metallurgical and construction materials enterprise, the impact testing machine is specifically designed to evaluate the impact toughness and anti-fracture performance of metal materials, including carbon steel, alloy steel, and stainless steel—key materials widely used in Turkey’s construction, automotive, and aerospace sectors. The equipment adheres to international standards such as ISO 148 and ASTM E23, ensuring its test results are recognized globally.

Equipped with a high-stability pendulum impact system, the machine offers adjustable impact energy ranging from 150J to 500J, catering to diverse testing needs of different material thicknesses and strengths. It features an intelligent control panel with a touch screen, enabling automatic test initiation, data acquisition, and result analysis, which reduces manual operation errors and improves testing efficiency by 40% compared to traditional models.

Notably, the machine is integrated with a high-definition camera and data storage module, which can record the entire impact process in real time and store test data for at least 10,000 times, facilitating traceability and review of test results. Its rugged structure, made of high-quality cast iron and anti-corrosion components, ensures stable operation even in harsh workshop environments with large temperature fluctuations, adapting to Turkey’s local industrial working conditions.

“We have conducted multiple rounds of rigorous performance tests and simulated on-site working conditions to ensure the machine fully meets the technical specifications and quality requirements of our Turkish client,” said the project director of the manufacturer. “This cooperation is a win-win: it helps our client upgrade their material testing capabilities and expands our footprint in the Turkish market, laying the groundwork for deeper cooperation in the future.”

After completion, the machine will be transported to the client’s production base in Istanbul via sea freight. It is expected to be commissioned within three weeks of arrival, providing reliable testing support for the client’s material quality control and product optimization. Whatsapp:+86 17860598665

Whatsapp:+86 17860598665

Email: sales02@jnkason.com

Whatsapp:+86 17860598665

Whatsapp:+86 17860598665Email: sales02@jnkason.com